You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

? Belts ?

- Thread starter JayQQ97

- Start date

Its a crap shoot with belts how long they might last. Some are just made far better quality than others. I can tell you once you spot any crack in them, its time for replacement. I recently replaced the belts in a snowblower i rebuilt the auger assembly on...both the drive belt, and auger belt were toast, with the drive belt nearly broken in half. On my new holland tractor I've got the same aftermarket clutch belts i've had on since the 80's that run my pto's that are still in decent shape. The originals failed in 15 years. Pretty hard to beat these mitsubishi belts. I think the original ones were dayco.

JayQQ97

MW surVivor ... clutched. 368k on the 0D0

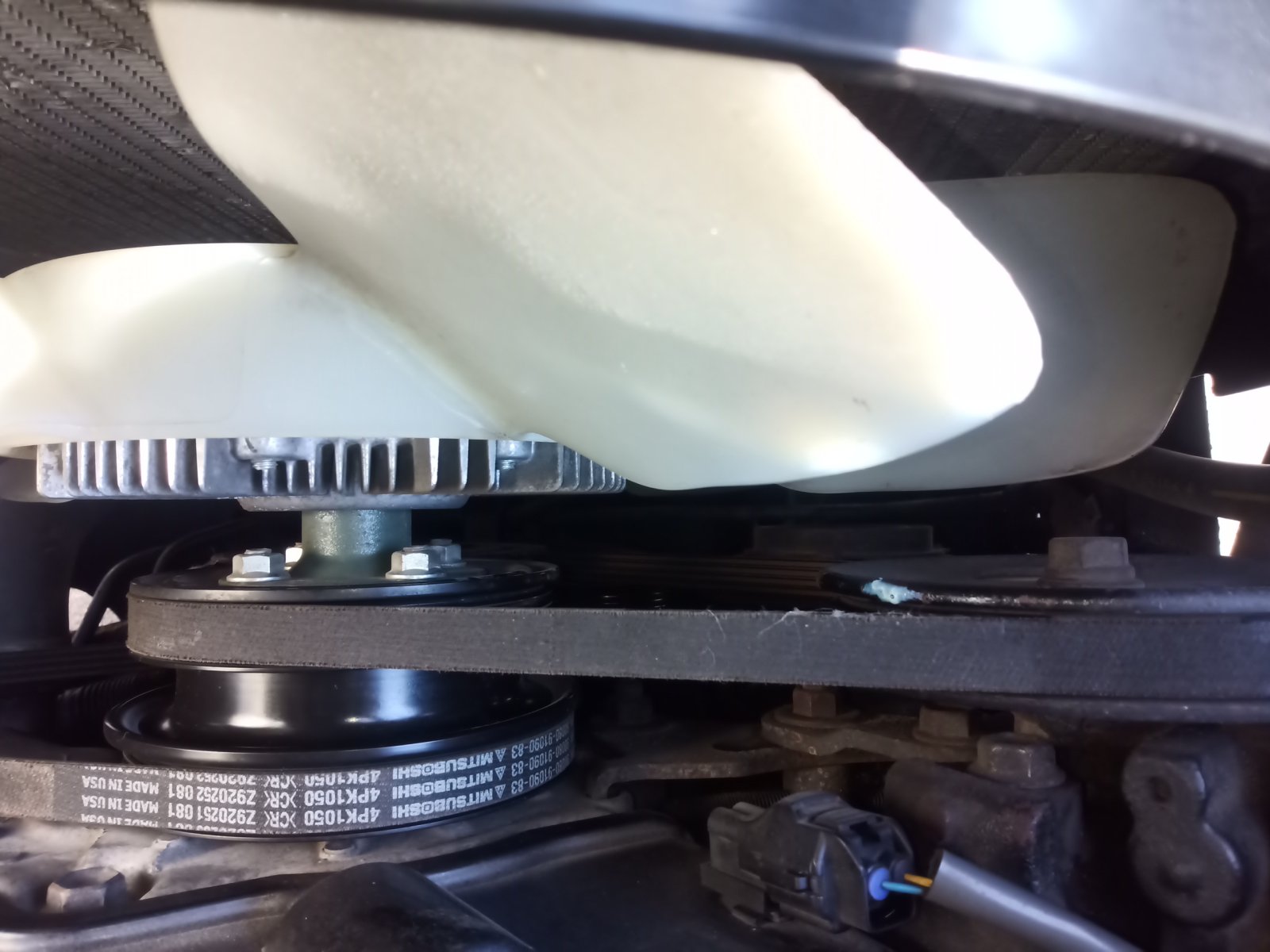

the current belts do appear to have some outer edge wear

i can compare edges with new belts when they arrive

when i changed that fan blade and the viscous fan clutch coupler i had issues removing it from the pulley,,, it was a bad day that day trying to bump it off but i was fortunate to be close to the ignition and turnt it off immediately before chit hit fan, literally....

but i was fortunate to be close to the ignition and turnt it off immediately before chit hit fan, literally....

i can compare edges with new belts when they arrive

when i changed that fan blade and the viscous fan clutch coupler i had issues removing it from the pulley,,, it was a bad day that day trying to bump it off

Rock62

Well-Known Member

Generally, it is best practice to relieve the belt tension before removing/replacing. Typically, belts are tensioned by a spring load tension pully or some accessory that slides on a bracket.

Good Lord man. Don't be daft and get hurt with poor mechanic skills.

FWIW, I've had very good experience using Gates belts and drive products.

Another way to tell if the belts are worn. Place a straight edge across the pulley flanges, if the top of the belt is below the flange edge, then belt is worn needing replacement.

Good Lord man. Don't be daft and get hurt with poor mechanic skills.

FWIW, I've had very good experience using Gates belts and drive products.

Another way to tell if the belts are worn. Place a straight edge across the pulley flanges, if the top of the belt is below the flange edge, then belt is worn needing replacement.

JayQQ97

MW surVivor ... clutched. 368k on the 0D0

It's more about the trepidation of getting injured due to health concerns (early rigor mortis onset) than lack of mechanics skills or no skills, put this here is on the level of a parts changer and not mechanic level in any way... I usually am limited to 1&half arms under the vehicle on my shoulder and any reaching with both arms does something in the cervical that is absolut paralyzing  brought me to my knees on many occasions...

brought me to my knees on many occasions...

They make decent snowmobile drive belt.i read dayco belts are absolut garbage

I've done that, but the belt isn't necessarily bad, they tend to stretch some over time causing that. I've had several belts look that way, but after resetting the tension they were fine for a very long time.Generally, it is best practice to relieve the belt tension before removing/replacing. Typically, belts are tensioned by a spring load tension pully or some accessory that slides on a bracket.

Good Lord man. Don't be daft and get hurt with poor mechanic skills.

FWIW, I've had very good experience using Gates belts and drive products.

Another way to tell if the belts are worn. Place a straight edge across the pulley flanges, if the top of the belt is below the flange edge, then belt is worn needing replacement.

JayQQ97

MW surVivor ... clutched. 368k on the 0D0

they do sell a products at the autoParts store

CRC belt dressing conditioner

is it a thing to ever do on the Yota?

879c for a small bottle

CRC belt dressing conditioner

is it a thing to ever do on the Yota?

879c for a small bottle

Rock62

Well-Known Member

eeggaads....

Avoid belt dressing. Its a messy bandaid at best. Its a sticky tar like substance with a tendency to goo up everything.

If the belt is slipping, then it is worn or needs to be tightened. Most likely the belt needs to be replaced.

Leave the Canned Mechanic on the store shelf. These miracles in a can seldom cure the problem, but they are good for making the wallet lighter.

Avoid belt dressing. Its a messy bandaid at best. Its a sticky tar like substance with a tendency to goo up everything.

If the belt is slipping, then it is worn or needs to be tightened. Most likely the belt needs to be replaced.

Leave the Canned Mechanic on the store shelf. These miracles in a can seldom cure the problem, but they are good for making the wallet lighter.

Rock62

Well-Known Member

To my knowledge there is no effective product to "prevent dry rot".

The belt flexes around every pulley transmitting power on the sides of the belt. Not the top or the bottom. Only the sides transmit power. When the top of the belt is below the pulley flange that is an indication of the belt sides are worn. Belts are pretty cheap, although can be a PITA to replace, they endure a huge number of cycles.

I consider them a maintenance item that needs inspection. Any cracks, glazing, frayed edges, concave sides, top below pulley flanges........replacement time. I've probably replaced a few prematurely, but I have never had a failed belt leave me stranded. I do a visual inspection at each oil change. I do this while waiting for the oil container to finish draining. Takes all of about 30-60 seconds to inspect.

The wide poly-v type belts are difficult to inspect for concave sides or top below pulley. Just look for cracks, glazing, frayed edges. Always look at both sides of the belt.

The belt flexes around every pulley transmitting power on the sides of the belt. Not the top or the bottom. Only the sides transmit power. When the top of the belt is below the pulley flange that is an indication of the belt sides are worn. Belts are pretty cheap, although can be a PITA to replace, they endure a huge number of cycles.

I consider them a maintenance item that needs inspection. Any cracks, glazing, frayed edges, concave sides, top below pulley flanges........replacement time. I've probably replaced a few prematurely, but I have never had a failed belt leave me stranded. I do a visual inspection at each oil change. I do this while waiting for the oil container to finish draining. Takes all of about 30-60 seconds to inspect.

The wide poly-v type belts are difficult to inspect for concave sides or top below pulley. Just look for cracks, glazing, frayed edges. Always look at both sides of the belt.