You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Clunking jerky feeling whilst shifting from P to R to D

- Thread starter JayQQ97

- Start date

JayQQ97

MW surVivor ... clutched. 369k on the 0D0

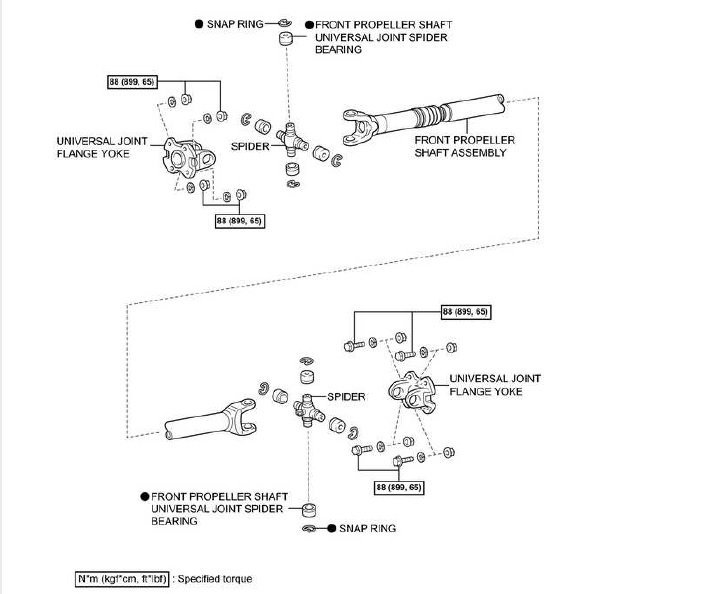

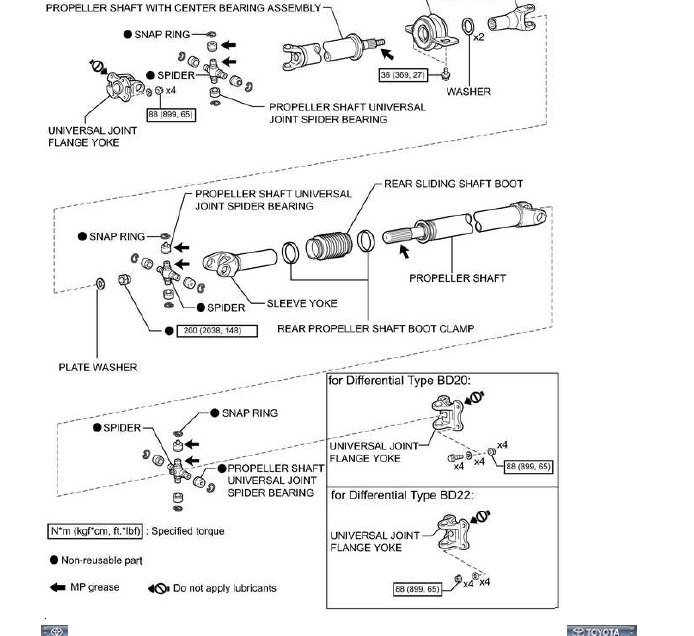

there are the torque specs the flange yokes need to be checked to see IF this is causing the noticeable intermittent clunking and rattling this truck has been experiencing since i got involved with it all

they are supposed to be checked every 5k miles per the Yota service sheet

and i assume they have not been checked in awhile IF EVER in 12yrs/70k miles

now i have to figure if two hands are need to hold the nut on oneside and check torque on the opposite bolt

JayQQ97

MW surVivor ... clutched. 369k on the 0D0

Apparently the standard 1/2 inch torque wrench and 14mm standard length socket will NOT fit to check the flange to spec

Would a wobbly 14mm have enough clearance at the flange yoke on the shaft

What do U use?

Rock62

Well-Known Member

I assume you are asking how I do this task.

I use an extension in the middle U-joint yoke to jam (prevent) the prop shaft from turning. No hands needed.

I use a torque wrench with a short extension and the socket. At worst, I'll use a universal joint on the extension to allow a little extra flex.

When setting the torque, I will keep the extension/universal as straight as practical (aligned with the bolt). Using one hand to support the proper alignment, the other hand applies the torque.

I use 3/8" drive sockets and extensions. The 1/2" drive torque wrench has a 1/2" to 3/8" adapter to mate with the 3/8" drive extensions and such.

I forget the exact torque level, but it isn't exceptionally high.

Good luck.

I use an extension in the middle U-joint yoke to jam (prevent) the prop shaft from turning. No hands needed.

I use a torque wrench with a short extension and the socket. At worst, I'll use a universal joint on the extension to allow a little extra flex.

When setting the torque, I will keep the extension/universal as straight as practical (aligned with the bolt). Using one hand to support the proper alignment, the other hand applies the torque.

I use 3/8" drive sockets and extensions. The 1/2" drive torque wrench has a 1/2" to 3/8" adapter to mate with the 3/8" drive extensions and such.

I forget the exact torque level, but it isn't exceptionally high.

Good luck.

JayQQ97

MW surVivor ... clutched. 369k on the 0D0

https://www.tekton.com/3-8-inch-drive-x-14-mm-universal-joint-socket-shd18114

I don't see them at tekton making a wobbly universal in 1/2 inch

Would one of those dummer down 1/2 to 3/8 work? I don't have one of those fittings either

I don't see them at tekton making a wobbly universal in 1/2 inch

Would one of those dummer down 1/2 to 3/8 work? I don't have one of those fittings either

Rock62

Well-Known Member

Beginning at the torque wrench......

1/2" drive torque wrench + 1/2" to 3/8" adapter + 3/8" extension + 3/8" universal joint (if needed) + 3/8" drive socket.

If the prop shaft "clunks" during rotation by hand when in Park, then I suspect you have a U-joint needing replacement or a loose flange. You may need to remove the prop shaft, take it to a driveshaft shop for inspection and corrective work.

Many times having the correct tool makes a job easy. Just about any Big Box store has a selection of decent mechanic tools, such as Kobalt, Husky, MasterForce..........numerous brands. Even Harbor Freight or Northern Tools.

1/2" drive torque wrench + 1/2" to 3/8" adapter + 3/8" extension + 3/8" universal joint (if needed) + 3/8" drive socket.

If the prop shaft "clunks" during rotation by hand when in Park, then I suspect you have a U-joint needing replacement or a loose flange. You may need to remove the prop shaft, take it to a driveshaft shop for inspection and corrective work.

Many times having the correct tool makes a job easy. Just about any Big Box store has a selection of decent mechanic tools, such as Kobalt, Husky, MasterForce..........numerous brands. Even Harbor Freight or Northern Tools.

Rock62

Well-Known Member

Agreed, that sounds like normal wear on high mileage vehicles.My gen1 tundra had a bit more than normal pinion to ring gear play when it got to that high mileage. Just the nature of the beast....parts wear out.

The parking pawl in the AT rarely has much wear. So, when in park the prop shaft should have very minimal play making it difficult to force a "clunk" sound. Based on the description of the sound, it seems probable a worn U-joint or a loose flange is the source.

Rock62

Well-Known Member

Snap-on brand has a decent selection of automotive tools

But damned be the price

Beginning at the torque wrench......

1/2" drive torque wrench + 1/2" to 3/8" adapter + 3/8" extension + 3/8" universal joint (if needed) + 3/8" drive socket.

Much less expensive than any Snap-On tool.

JayQQ97

MW surVivor ... clutched. 369k on the 0D0

14mm 3/8 inch and the stubby appears to be good for clearanceI even tried the new 1/2 inch 6 inch extension just bot from tekton and still no clearance around that joint

Buy yet another torque wrench if my old stubby stubby 3/8 extension fits well?

Now I must concern about ground clearance torque wrench

JayQQ97

MW surVivor ... clutched. 369k on the 0D0

still there is this clunky... but NOT all the time. so i do not get it get it at all!?

to properly check that rear-most uJoint that likely has NOT ever been greased with new red tacky until i did it (watery oozed out then)

to properly check would the driveshaft need to be undone from 3rd memeber to get a better feel onit?

to properly check that rear-most uJoint that likely has NOT ever been greased with new red tacky until i did it (watery oozed out then)

to properly check would the driveshaft need to be undone from 3rd memeber to get a better feel onit?