You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

needing a new MT clutch procedure

- Thread starter JayQQ97

- Start date

Rock62

Well-Known Member

JayQQ97

MW surVivor ... clutched. 369k on the 0D0

Transmission R-155 manual transmission information . Your 5 speed transmission (WRITE UP )

This post is dedicated to the R-155 manual transmission . All you guys with the 5 speed should read through some of this stuff .If you have additional...

CHECK YOUR CLUTCH ADJUSTMENT !!!!! DONT WAIT FOR YOUR THROW OUT BEARING TO BLOW UP. Some of you are just reading this now and may be too late

This will help you determine if you need a new bearing .

Your throw out bearing is semi-centrifical which means its only pre-loaded when you push your pedal down .When your foot is off the clutch pedal , the throw out bearing is NOT suppose to turn and shouldnt be pre-loaded against the pressure plate fingers .The adjustment is made under the dash at the pedal and master pushrod adjustment .As your clutch wears in , the throw out bearing begins to turn all the time and wears the bearing out premature unless a clutch adjustment is made . The chirping you are hearing is the point in time where your throw out bearing begins to touch the pressure plate fingers .The pressure plate is spinning and the throw out bearing is stationary . Your clutch is starting to wear in a little and this is an early warning that its time to re-adjust the clutch and is how these clutches have operated for very long time .

When this happens , The sound will only be noticeable in neutral with the truck running . When you push the clutch pedal down , the throw out bearing will start turning and the chirping will go away .Some people believe that the bearing is suppose to turn all the time which is totally incorrect .The throw out bearing is "not" designed to be preloaded against the fingers of the pressure plate . Other members make adjustments to their clutch without knowing how a diaphram style clutch works and tell the world they fixed the chirping but really all they did was make the bearing turn all the time - the noise went away so it must be fixed " WRONG " Wrong Wrong .

A diaphram style clutch works like a pivot . As the clutch disc wears in , the fingers on the pressure plate move towards the throw out bearing . Anyone who has changed out their clutch will notice as you are bolting down the new pressure plate to the flywheel , the pressure plate fingers will move outwards towards the release bearing until you have all the bolts torqued down . The same thing occurs as your clutch disc begins to wear in.THE PRESSURE PLATE FINGERS MOVE TOWARDS THE RELEASE BEARING .

Even if you have a new clutch installed at a garage , make sure the free play adjustment is done correctly since some mechanics skip this step and actually use procedures used by Ford to fix your Toyota and accidently send you on your way with a spinning preloaded bearing .Your new bearing is "NOT " going to last as long if its preloaded against the pressure plate fingers because preloading increases as the clutch disc begins to wear .This means that when the clutch is new and adjusted correctly , there is no weight on the bearing . As the clutch disc starts to break in , the weight on the bearing doubles .Print out the FSM free play adjustment and take it to the shop thats doing your clutch job so they have instructions to follow .

There are other issues with the throw out bearing . The above issue is only one of them .

Last edited:

JayQQ97

MW surVivor ... clutched. 369k on the 0D0

Transmission R-155 manual transmission information . Your 5 speed transmission (WRITE UP )

Has anyone (@gearcruncher :boink:) come across a dimension for the R155F input shaft end, specifically where it mates the pilot bearing? Even the ID of...

Grab a new pilot bearing and try slipping it onto the input shaft . Does the pilot bearing wobble when you move it back and fourth ? If yes , the input shaft needs replacement . The only time the pilot bearing is in use is when you have your clutch pedal down . The spinning clutch disc is pulled away from the flywheeel and this is when the pilot bearing begins supporting the spinning clutch disc . You will hear noise when the clutch is pushed down .

JayQQ97

MW surVivor ... clutched. 369k on the 0D0

i have not ever had an issue with it popping out-of-gear

not ever in 26+ years and 341k miles

very strange...

www.instructables.com

www.instructables.com

not ever in 26+ years and 341k miles

very strange...

Toyota Tacoma Manual Transmission Pop Out of Gear? Here's the Simple Fix!

Toyota Tacoma Manual Transmission Pop Out of Gear? Here's the Simple Fix!: If you have a Toyota truck with a manual transmission with a considerable amount of miles on it, there's a good chance that you suffer from a common problem that these trucks have. Gears that pop out of gear while...

JayQQ97

MW surVivor ... clutched. 369k on the 0D0

diagnostics...

grindy noise throwing into 2nd from 1st

noise heard but not necessarily felt in the stick shifter

what is that?

was that the blasted pilot bearing freezing up

i'm curious now if THIS noise was the input shaft bearing? that is outside of the transmission housing

it was found to be a bit wobbly..

JayQQ97

MW surVivor ... clutched. 369k on the 0D0

Smell of gear oil persists after transmission rebuild with no leaks

Hey y’all, So my problem is I smell gear oil when I’m driving with the windows down. Especially on a steep uphill grade in second gear. I never had...

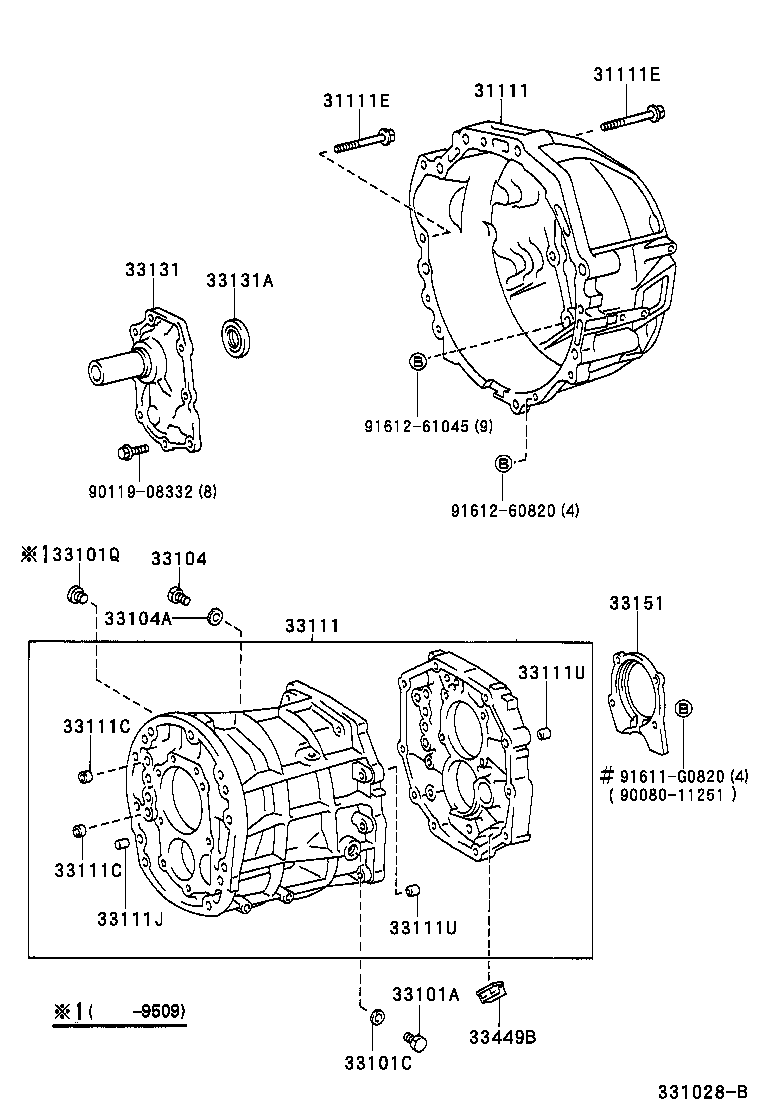

Bellhousing Identification Trouble

Hey Everyone, I was wondering if I could get some help identifying what bellhousing I have on my truck: I unfortunately had the clutch fork pivot...

Bellhousing issue? Is this common?

Hi there, I brought my 2002 V6 TRD 5sp MT tacoma into the shop because I was having trouble getting it into 1st gear and reverse from cold stop. Every...

Last edited:

JayQQ97

MW surVivor ... clutched. 369k on the 0D0

Bellhousing issue? Is this common?

Hi there, I brought my 2002 V6 TRD 5sp MT tacoma into the shop because I was having trouble getting it into 1st gear and reverse from cold stop. Every...

In most cases , you begin a first and reverse diagnosis by replacing the clutch master and clutch slave cylinder .

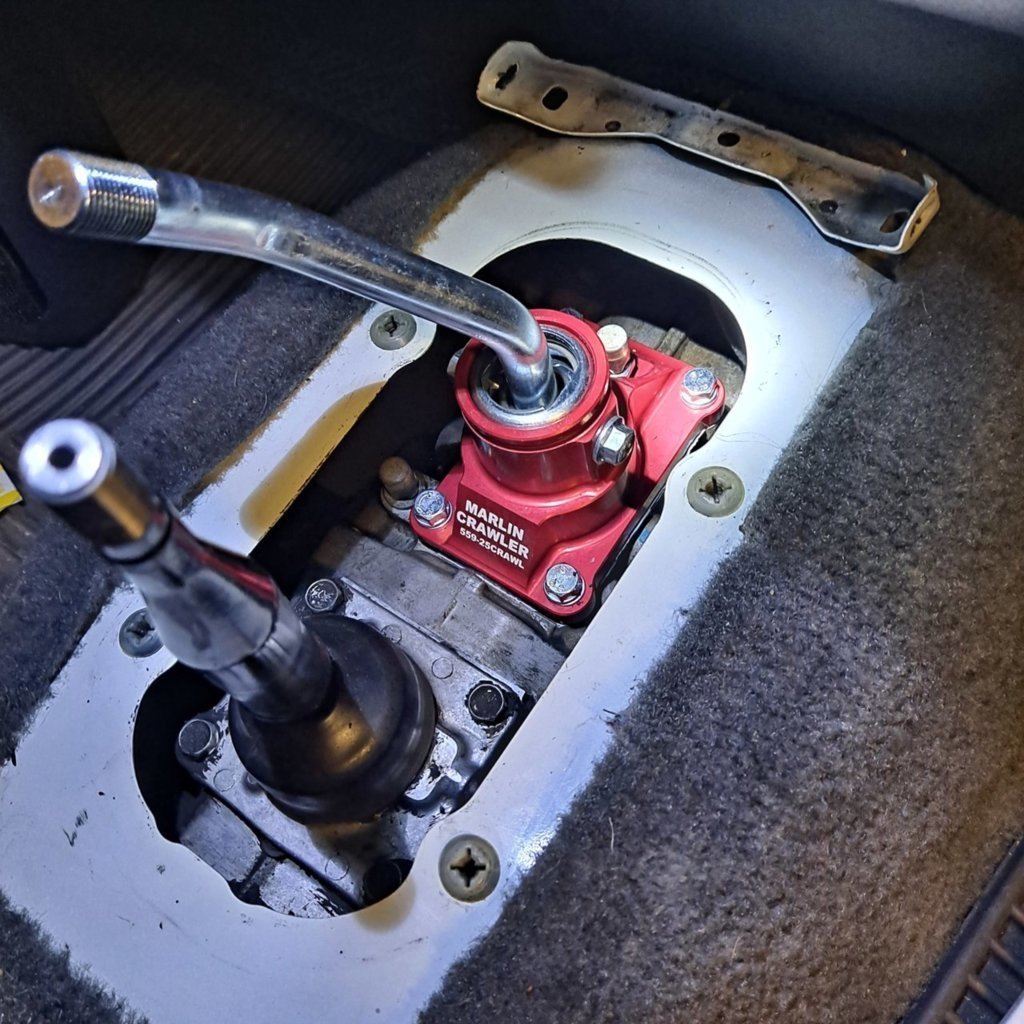

This way the hydraulic components are new . From there , a fresh shifter bushing should be installed

Next , When you Push your clutch pedal to the floor using a stethoscope , you can hear the transmission input shaft come to a stop . If you cant hear the input shaft come to a stop in a timely fashion , replace the clutch

Last edited: