You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

needing a new MT clutch procedure

- Thread starter JayQQ97

- Start date

JayQQ97

MW surVivor ... clutched. 369k on the 0D0

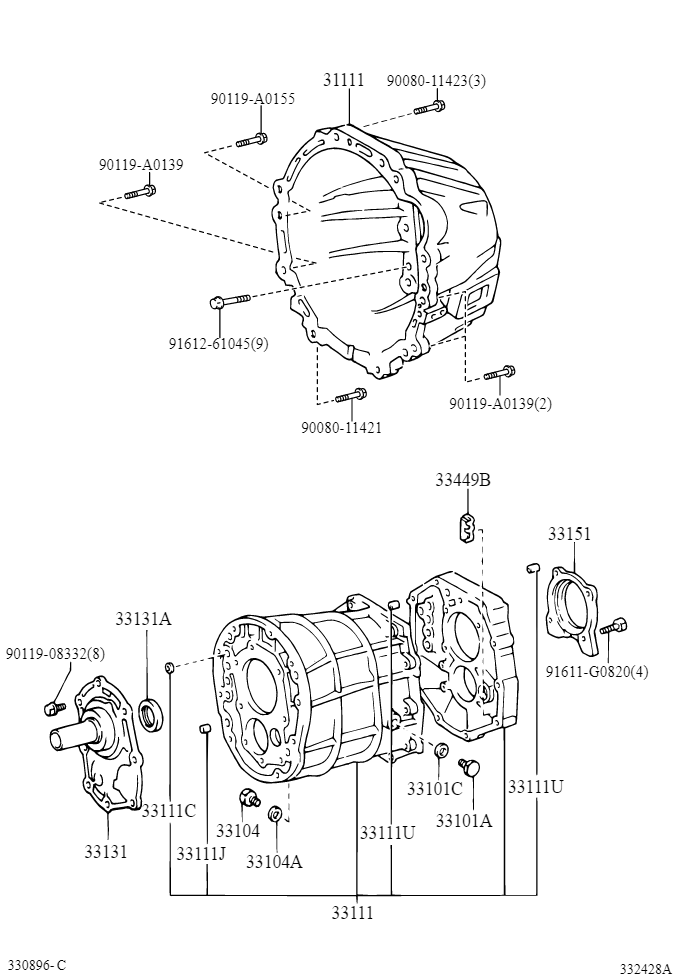

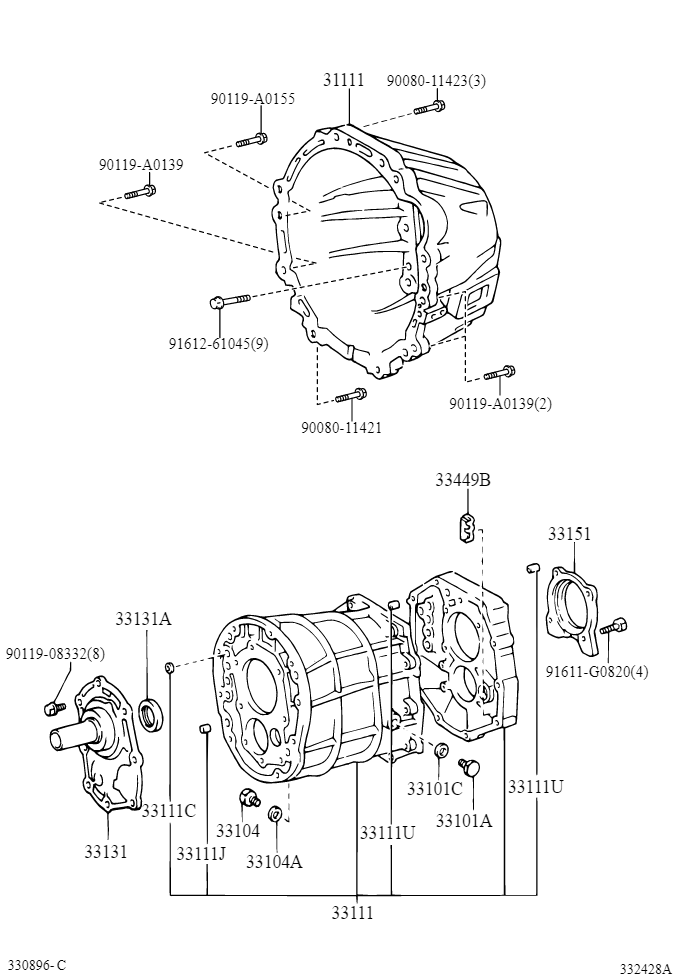

perhaps this part is the culprit of the odd noisy under 2k rpm in 2nd through 5th gears

is it common practice to replace this during the clutch procedure?

front retainer bearing

86$ 31off 125$ msrp

https://autoparts.lewistoyota.com/products/product/retainer-bearing-fr-3313135031

part 33131 on diagram

there is also a seal behind it

is it common practice to replace this during the clutch procedure?

front retainer bearing

86$ 31off 125$ msrp

https://autoparts.lewistoyota.com/products/product/retainer-bearing-fr-3313135031

part 33131 on diagram

there is also a seal behind it

JayQQ97

MW surVivor ... clutched. 369k on the 0D0

I think I mentioned some days ago in a thread to always change the throwout bearing when doing a clutch replacement. Have the flywheel resurfaced also. Its just stupid not to.

As far as your diagram...that picture doesn't show a throwout bearing in it.

yes this is a different diagram of parts relating to the part i believe the throwout bearing is attached to from watching recent dissassembly video from Petr in California on that gen2 taco bearing

JayQQ97

MW surVivor ... clutched. 369k on the 0D0

I think I mentioned some days ago in a thread to always change the throwout bearing when doing a clutch replacement. Have the flywheel resurfaced also. Its just stupid not to.

As far as your diagram...that picture doesn't show a throwout bearing in it.

clutch housing transmission case section

TOYOTA TACOMAVZN170L-CRMGKAB - POWERTRAIN-CHASSIS - CLUTCH HOUSING TRANSMISSION CASE MTM | Japan Parts EU

TOYOTA TACOMAVZN170L-CRMGKAB , CLUTCH HOUSING TRANSMISSION CASE MTM

Rock62

Well-Known Member

Well.....I s'pose you could keep guessing.

Or............

Take it to a SHOP for repair/replacement.

Simple path to offer comfort on the procedure.

1. Speak with the mechanic only describing the symptoms. DO NOT offer a diagnosis.

2. Let the mechanic diagnose the issue.

3. Have the mechanic give details of the diagnosis and provide a quote for the complete repair in writing.

3a. Ask about a warranty. Should be written, not verbal.

4. You need to approve or deny the repair.

5. Assuming you approve. Request to have all the removed parts returned to you.

6. Use the returned parts to verify the parts on the final invoice.

7. Test drive it before you pay. Take the mechanic with you if possible.

8. Request the warranty in WRITING.

9. Pay the complete invoice.

Good Luck.

Or............

Take it to a SHOP for repair/replacement.

Simple path to offer comfort on the procedure.

1. Speak with the mechanic only describing the symptoms. DO NOT offer a diagnosis.

2. Let the mechanic diagnose the issue.

3. Have the mechanic give details of the diagnosis and provide a quote for the complete repair in writing.

3a. Ask about a warranty. Should be written, not verbal.

4. You need to approve or deny the repair.

5. Assuming you approve. Request to have all the removed parts returned to you.

6. Use the returned parts to verify the parts on the final invoice.

7. Test drive it before you pay. Take the mechanic with you if possible.

8. Request the warranty in WRITING.

9. Pay the complete invoice.

Good Luck.

JayQQ97

MW surVivor ... clutched. 369k on the 0D0

my experiences with monkey slopshops, have tried several local in the past 4 years, is absolut total retarded shi!t

which makes me much more disgruntled that i can possibly be

paid some good coin for absolut sh!t gets into your system and starts boiling LMAO

which makes me much more disgruntled that i can possibly be

paid some good coin for absolut sh!t gets into your system and starts boiling LMAO

JayQQ97

MW surVivor ... clutched. 369k on the 0D0

the first oddity i had EVER experienced i described the infrequent symptoms for many months to years to find out what exactly is wrong and get it fixed proper

because it only popped up under certain conditions they would NOT EVER be able to replicate it most likely... until that finally broke and launched into a moving engine fan blade

that was professionally diagonsed as 'clutch throwout bearing chatter' by an ASE certified master Toyota technician and was verified as the issue TWICE before i believed them much to my dismay ... this was nearly 150k miles ago

because it only popped up under certain conditions they would NOT EVER be able to replicate it most likely... until that finally broke and launched into a moving engine fan blade

that was professionally diagonsed as 'clutch throwout bearing chatter' by an ASE certified master Toyota technician and was verified as the issue TWICE before i believed them much to my dismay ... this was nearly 150k miles ago

Rock62

Well-Known Member

Follow those 9 simple steps will give you confidence to vette the shop and to check the work and to have legal recourse.

If the mechanic won't detail the diagnosis or the repair or offer a warranty walk away.

If they won't offer a detailed quote with parts and labor, then walk away. Be aware, additional work maybe discovered during the repair. This work should fall into the same procedure.

If you do not approve of the additional work and the shop performs the work, then you are not responsible for the cost of the additional work.

Intermittent problems are the most difficult to isolate and diagnose.

This is why you ask for details of the diagnosis. If the details seem wonky, then seek a 2nd opinion from another shop.

You need to take prudent steps to protect your wallet and property.

If the mechanic won't detail the diagnosis or the repair or offer a warranty walk away.

If they won't offer a detailed quote with parts and labor, then walk away. Be aware, additional work maybe discovered during the repair. This work should fall into the same procedure.

If you do not approve of the additional work and the shop performs the work, then you are not responsible for the cost of the additional work.

Intermittent problems are the most difficult to isolate and diagnose.

This is why you ask for details of the diagnosis. If the details seem wonky, then seek a 2nd opinion from another shop.

You need to take prudent steps to protect your wallet and property.

JayQQ97

MW surVivor ... clutched. 369k on the 0D0

intermittent problems are difficult and challenging for the 'parts changers'

but ought not all that difficult for the true and bonafide 'master mechanics' that know what it is going on by simple descriptions and have seen it all before

and are not just 'parts changers'

but ought not all that difficult for the true and bonafide 'master mechanics' that know what it is going on by simple descriptions and have seen it all before

and are not just 'parts changers'

Rock62

Well-Known Member

Yeah, I think that is the path he is pursuing.Well, jay could always continue to drive the truck till it blows up. This has been a tried, and true method of '' don't fix it if it ain't broke.''

The downside is then he won't have any choice along with additional towing fees.

I wonder if a pool should be started betting on what breaks down first. Engine, Transmission, Suspension.....Other.

JayQQ97

MW surVivor ... clutched. 369k on the 0D0

Well, jay could always continue to drive the truck till it blows up. This has been a tried, and true method of '' don't fix it if it ain't broke.''

other would be a decent guess...

broke in Syracuse NY and remedied (for time being) in Jamestown NY, home of the 10,000 Maniacs

1000 miles away from home

Lets start a poll on this.Yeah, I think that is the path he is pursuing.

The downside is then he won't have any choice along with additional towing fees.

I wonder if a pool should be started betting on what breaks down first. Engine, Transmission, Suspension.....Other.

JayQQ97

MW surVivor ... clutched. 369k on the 0D0

I recall mentioning a time ago how difficult it has been to find a yota specialist shop that will resurface flywheel if it's still good and can be doneI think I mentioned some days ago in a thread to always change the throwout bearing when doing a clutch replacement. Have the flywheel resurfaced also. Its just stupid not to.

As far as your diagram...that picture doesn't show a throwout bearing in it.

Everybody wants to just put a new one in and charge the extra 400$ or so to 700$+. For just that part

400$ is for a non OEM part so likely jank

A toyota dealer likely won't resurface a flywheel, they're going to farm it out to a machine shop. It shouldn't cost anywhere near what a new flywheel costs. A buddy of mine that runs a large auto repair shop does this all the time when replacing clutch's, as long as there's still enough flywheel material to work with.